Murray-Dick-Fawcett House Roof Restoration (Phase I)

Murray-Dick-Fawcett House Roof Restoration (Phase I)

Roof restoration at the Murray-Dick-Fawcett House at 517 Prince Street took place in 2021-2022. Work was carried out by Oak Grove Restoration Company on behalf of the City of Alexandria. The following description of the work was provided by Oak Grove.

Roof Restoration Plan

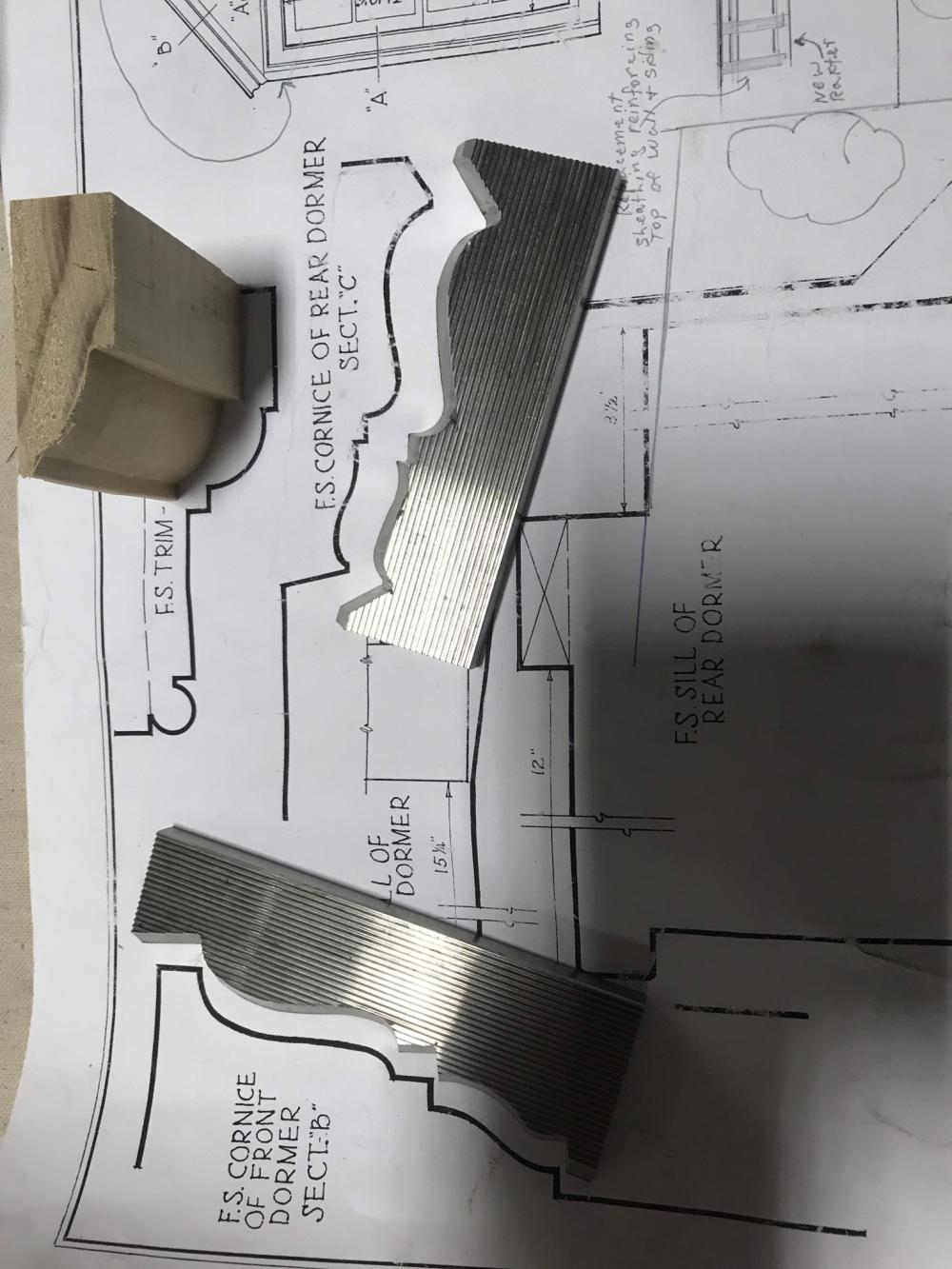

The roof restoration plan, or scope of work for this project, was to replace the standing seam metal roof at the cat slide roof and the 1797 addition, and to install a new fish scale wood shingle roof on the south elevation of the original 1772 section of the Murray-Dick-Fawcett House. This work also included the restoration of the two dormers on the south side of the 1772 section and two dormers on the west side of the 1797. The final task was to restore the cornice to its original design.

The approach throughout the project was to rebuild each section with materials matching the original products as closely as possible and to mill each new part to seamlessly fit into the original construction.

Reinforcing the Roof Framing

The long span of the cat slide roof rafters were reinforced by installing a new structural wall inside the attic. The wall has a beam running across the tops of the attic floor joist. Individually sized blocks are fastened to the top of each floor joist to create a level plain for the bottom beam. All the joints are reinforced with metal angle brackets and screwed in place.

Restoring the South Dormers

As the modern carpentry work was peeled off the dormers, the original heavy timber frame structure of the window frames emerged. Unfortunately the frame had large areas of rot which had been hidden by the modern carpentry work. Following our restoration plan, we repaired the original materials and restored the dormers to their original design while saving and reusing all the original fabric.

Restoring the West Dormers

The west dormers on the 1797 section survived largely intact. One of the original window sills had been replaced. Using the original sill as a guide, a new sill was milled to match.

Original Fish Scale Shingles

In 1784, when the original house was expanded, a cat slide roof was built over the north side of the original roof, leaving the first period roof framing and shingles preserved beneath it. The encapsulated historic wood shingles provided the design details for the new wood shingles we would mill for exposed wood shingles on the south elevation.

Making New Fish Scale Shingles

Not being able to match the wood species used to make 1772 roof shingles. The team decided to use Alaskan yellow Cedar also known as Nootka Cypress. This is the hardest known Cedar. The shingles were purchased directly from a mill in British Columbia. The shingles are 24" long and at the bottom edge they are 5/8" thick. They come random width but are generally 6" to 12" wide.

Restoring the Roof Deck and Installing Wood Shingles

The existing wooden roof on the south side of the house was completely worn out. Repairing the roof deck was straightforward. We replaced some of the skip sheathing and covered it with plywood, a waterproof membrane called an ice and water shield, a layer called cedar breather, and finally, the new cedar shingles.

Preparing Wood Decks for Metal Roofing

As Oak Grove removed the terne metal roof at the north edge of the cat slide roof, we uncovered several rotted roof sheathing boards. Years of rain water leaking into the roof framing and walls below had damaged much more than just the roof sheathing. Along this section of roof we replace rotted roof rafters, attic flooring, attic floor joists, top of wall beam, wall studs, sill plate window frames and historic wood siding. The footing and foundation wall also had to be repaired.

Prior to any jacking or leveling, the historic plaster ceilings had to be reinforced and consolidated with fabric that is glued to the back side of the plaster and wooden lath, bonding the ceiling system together. After the consolidant had dried, the ceiling and its framing was jacked back into position.

Rebuilding the Roof Cricket

Where the bottom of the catslide roof meets the 1797 brick addition, a difficult design problem was created. The gable end of the brick addition butted directly into the eave of the earlier roof. This condition was corrected by building a large cricket at the bottom of the catslide roof to divert the water around the gable end of the brick addition.

Originally the cricket was not built quite wide enough to divert all the water, which added to the extensive water damage at the south wall of the brick addition.

As part of the roof framing repairs Oak Grove rebuilt the cricket, making it wider so the rain runoff would clear the sides of the addition and flow freely into the new gutter system.

Roofinox Stainless Steel Roof

Matching the historic standing seam roof was not possible because the original terne metal had a substantial component of lead. Roofinox, a German roofing material made from 316 stainless steel, matches the appearance of the historic terne metal roofing without using lead. Wagner Roofing installed the metal roof.